Welding Cable & Battery Cable

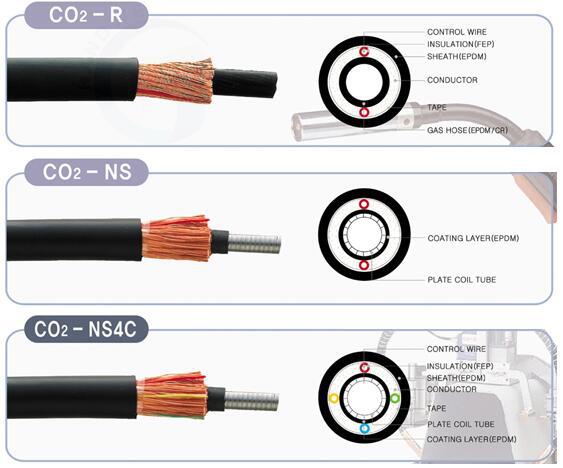

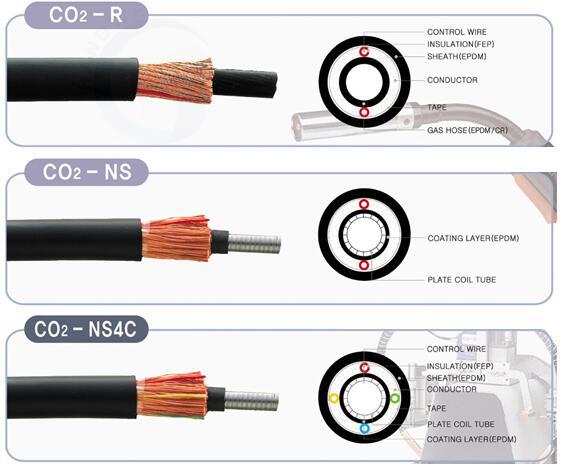

CO2/MIG/MAG Weld torch Cable for Arc welding Machine XLPE Sheathed Kabel Wire

- Inner tube: thermoplastic elastomer.

- Conductor: Stranded BC, or Tinned copper

- Insulation: XLPE

- Outer Jacket: XLPE

- Product description: CO2/MIG/MAG Weld torch Cable for Arc welding Machine XLPE Sheathed Kabel Wire Inner tube: thermoplastic elastomer. control core Conductor: Stranded BC, or Tinned copper Insulation: XLPE, blue, br

CO2/MIG/MAG Weld torch Cable for Arc welding Machine XLPE Sheathed Kabel Wire

application

This cable is used to connect the welding machine and the CO2/MIG/TIG/MAG welding torch. CO2 is passed through the inner tube as a shielding gas. It has many advantages such as high conductivity, good flexibility, crack-proof, aging-proof, wear-proof, oil-proof, corrosion-proof, high temperature-proof, flame retardant, low smoke and non-toxicity. Special cable for secondary side connection of welding machine.The connection between the electrode holder and the welding machine.

Standard

Enterprise standard

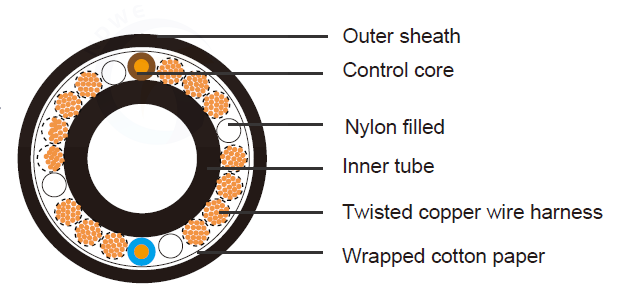

cable structure

Inner tube: thermoplastic elastomer.

control core

Conductor: Stranded BC, or Tinned copper

Insulation: XLPE, blue, brown.

Twisted pair copper wire harness: Stranded annealed copper (minimum 99.95% copper)

nylon filling

Wrap Tissue: Spiral over copper strands and control cores.

Outer Jacket: XLPE, blue, brown.

skills requirement

1. Inner tube hardness: Shore 90-95.

2. The maximum long-term working temperature of the conductor: 125℃.

3. The minimum bending radius of the cable: ≥6×OD.

4. Outer Jacket hardness: Shore 85±5.

Cable Datas:

NOMINAL Section mm²

DRIVER NO./ DIA. Hmm

NOMINAL Jacket THICK.mm

WRAP THICK. mm

Cable OD DIA. mm

CONDUCTOR

CONTROL WIRE

INNER DIA.×

NOMINAL Section mm²

NO. OF Wire

THICK. mm

70

3486/0.16

2

0.1

21.3

8×1.5

0.75

2

60

2986/0.16

2

0.1

21.3

8×1.5

0.75

2

56

2787/0.16

2

0.1

20.5

8×1.5

0.75

2

52

2588/0.16

2

0.1

20.5

8×1.5

0.75

2

50

2489/0.16

2.0

0.1

20.5

8×1.5

0.75

2

35

1742/0.16

2

0.1

19.4

8×1.5

0.75

2

30

1493/0.16

2

0.1

17.8

7×1.4

0.75

2

25

1244/0.16

1.7

0.1

15.5

6×1.1

0.75

2

16

798/0.16

1.7

0.1

14.7

6×1.1

0.75

2

10

504/0.16

1.5

0.1

14

6×1.1

0.75

2

70

3486/0.16

2

0.1

21.3

8×1.5

0.5

2

65

3234/0.16

2

0.1

21.3

8×1.5

0.5

2

56

2787/0.16

2

0.1

20.5

8×1.5

0.5

2

52

2588/0.16

2

0.1

20.5

8×1.5

0.5

2

50

2489/0.16

2

0.1

20.5

8×1.5

0.5

2

45

2240/0.16

2

0.1

20.5

8×1.5

0.5

2

35

1742/0.16

2.0

0.1

19.4

8×1.5

0.5

2

30

1493/0.16

2

0.1

17.8

7×1.4

0.5

2

25

1244/0.16

1.7

0.1

15.5

6×1.1

0.5

2

16

798/0.16

1.7

0.1

14.7

6×1.1

0.5

2

14

700/0.16

1.7

0.1

16.4

7×1.4

0.5

2

13

647/0.16

1.7

0.1

14

6×1.1

0.5

2

10

498/0.16

1.5

0.1

14

6×1.1

0.5

2

70

3486/0.16

2

0.1

21.3

8×1.5

0.3

2

60

2986/0.16

2

0.1

21.3

8×1.5

0.3

2

56

2787/0.16

2

0.1

20.5

8×1.5

0.3

2

52

2588/0.16

2

0.1

20.5

8×1.5

0.3

2

50

2489/0.16

2

0.1

20.5

8×1.5

0.3

2

35

1742/0.16

2

0.1

19.4

8×1.5

0.3

2

30

1493/0.16

2

0.1

17.8

7×1.4

0.3

2

25

1244/0.16

1.7

0.1

15.5

6×1.1

0.3

2

16

798/0.16

1.7

0.1

14.7

6×1.1

0.3

2

14

700/0.16

1.7

0.1

16.4

7×1.4

0.3

2

13

647/0.16

1.7

0.1

14

6×1.1

0.3

2

10

498/0.16

1.5

0.1

14

6×1.1

0.3

2

Cable Photos:

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Richard Li

Phone: 0086-13396732591

Tel: 0086-13396732591

Email: richard@handwecable.com

Add: Floor 5, No. 137-138, Lane No. 456, Dieqiao Road,Pudong New District, Shanghai, China

+8613396732591

+8613396732591 +8613396732591

+8613396732591 Handwe Industry

Handwe Industry Handwe Industry

Handwe Industry