Welding Cable & Battery Cable

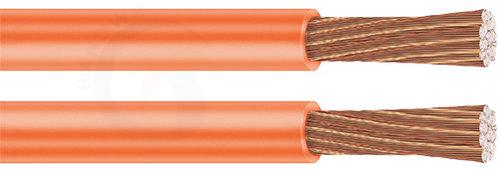

Rubber H01N2-D H01N2-E Welding Cable Pure Copper or CCA Wire 0.6/1KV Kabel for ARC Weld machine

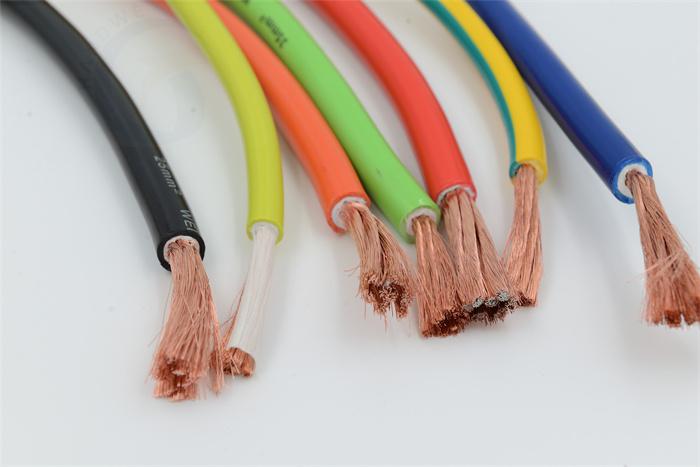

- Conductor:Bare Copper, Tinned Copper, CCA

- Optional EPR/EPDM insulation

- Jacket: Neoprene/NBR//EPR/CPE

- Standard:VDE 0295, BS 6360, IEC 60228, HD 383

- Product description: Rubber H01N2-D H01N2-E Welding Cable Pure Copper or CCA Wire 0.6/1KV Kabel for ARC Weld machine - Stranded ultra-soft bare copper or tinned copper conductors - PP insulation layer - Optional EPR/EP

Rubber H01N2-D H01N2-E Welding Cable Pure Copper or CCA Wire 0.6/1KV Kabel for ARC Weld machine

Applications: Lead wire for welding machine., Autocar Jumper Leads, Battery chargers, power applications,Switchboards, busbars, transformers.

The wire cables are used for the connection between the welding generator, the manual electrode and the workpiece. Used in the automotive industry, shipbuilding, transportation and conveying systems, tool-making machinery, welding robots, etc., this cable maintains its high flexibility even under the influence of ozone, light, oxygen, shielding gases, oil and gasoline. Its durable cable construction makes them resistant to low temperature, high temperature, fire, ozone, radiation, oil, acid, fat and gasoline. Suitable for outdoor installation in dry or damp places.

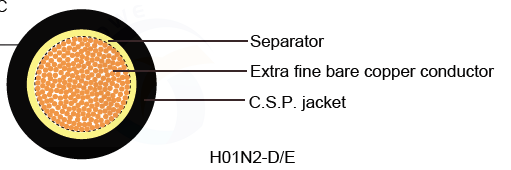

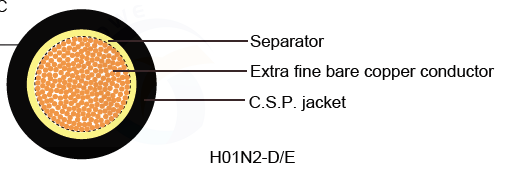

Cable structure

- Stranded ultra-soft :Bare Copper, Tinned Copper, CCA(Copper Clad Aluminum) wire

- Complies with DIN VDE 0295, BS 6360, IEC 60228, HD 383

- PP insulation layer

- Optional EPR/EPDM insulation

- Neoprene/NBR//EPR/CPE Jacket EM5

Standards and Certifications

IEC 60332.3, IEC 60754.1, VDE-0282 P-6,HD22.6 S2, UNEL 35368, CEI 20-22 II, CEI 20-38, CE Low Voltage Directives 73/23/EEC & 93/68/EEC. , ROHS certification

Technical characteristics

- Working voltage: 100/100 V

- Test voltage: 1000 V

- Dynamic bending radius: 12.0 x Ø

- Fixed installation bending radius: 7.5 x Ø

- Operating temperature during application: -25º C to +80º C

- Fixed installation temperature: -40º C to +80º C

- Flame retardant: IEC 60332.

Cable sizes and datasheet:

Note: For any other cable sizes and CCA (Copper Clad Aluminum) welding cables are available, welcome for inquiry.

Normal Cable data sheet

CORE NO. X NOMINAL SECTION

COND. STRUCT.

NOMINAL INSU. THICK.

NOMINAL OD

CU WEIGHT

Cable WEIGHT

# X mm2

# X mm

mm

mm

kg/km

kg/km

1 x 10

318/0.2

2

7.7-9.7

96

135

1 x 16

509/0.2

2

8.8-11.0

154

205

1 x 25

796/0.2

2

10.1-12.7

240

302

1 x 35

1114/0.2

2

11.4-14.2

336

420

1 x 50

1592/0.2

2.2

13.2-16.5

480

586

1 x 70

2228/0.2

2.4

15.3-19.2

672

798

1 x 95

3024/0.2

2.6

17.1-21.4

912

1015

1 x 120

3820/0.2

2.8

19.2-24.0

1152

1310

1 x 150

4775/0.2

3

21.2-26.4

1440

1620

1 x 185

5889/0.2

3.2

23.1-28.9

1776

1916

1 x 240

7639/0.2

3.4

25.0-29.5

2304

2540

EXTREME FLEX Cable data sheet

CORE NO. X NOMINAL SECTION

COND. STRUCT.

NOMINAL INSU. THICK.

NOMINAL OD

CU WEIGHT

Cable WEIGHT

# X mm2

# X mm

mm

mm

kg/km

kg/km

1 x 10

884/0.12

1.2

6.2-7.8

96

119

1 x 16

1415/0.12

1.2

7.3-9.1

154

181

1 x 25

2210/0.12

1.2

8.6-10.8

240

270

1 x 35

3095/0.12

1.2

9.8-12.3

336

363

1 x 50

4421/0.12

1.5

11.9-14.8

480

528

1 x 70

6189/0.12

1.8

13.6-17.0

672

716

1 x 95

8400/0.12

1.8

15.6-19.5

912

1012

1 x 120

10610/0.12

1.8

17.2-21.6

1152

1190

1 x 150

13263/0.12

1.8

18.8-23.5

1440

1305

1 x 185

16358/0.12

1.8

20.4-25.5

1776

1511

Note: For any other cable sizes and CCA (Copper Clad Aluminum) welding cables are available, welcome for inquiry.

H01N2-D Weld Cable Size Chart & Data sheet

Cable Section

Wire No.

Wire Size

Jacket Thick.

Nominal OD

Max.Cond. Resist. at 20℃

Min.

Max.

TC

BC

mm²

mm

mm

mm

mm

≤Ohm/km

10

320

0.2

2

7.7

9.7

1.95

1.91

16

513

0.2

2

8.8

11

1.19

1.16

25

798

0.2

2

10.1

12.7

0.78

0.758

35

1115

0.2

2

11.4

14.2

0.552

0.536

50

1596

0.2

2.2

13.2

16.5

0.39

0.379

70

2214

0.2

2.4

15.3

19.2

0.276

0.268

95

2997

0.2

2.6

17.1

21.4

0.204

0.198

120

612

0.2

2.8

19.2

24

0.164

0.161

H01N2-E Weld Cable Size Chart & Data sheet

Cable Section

Wire No.

Wire Size

Jacket Thick.

Nominal OD

Max.Cond. Resist. at 20℃

Min.

Max.

TC

BC

mm²

mm

mm

mm

mm

≤Ohm/km

10

497

0.16

1.2

6.2

7.8

1.95

1.91

16

791

0.16

1.2

7.3

9.1

1.19

1.16

25

1241

0.16

1.2

8.6

10.8

0.78

0.758

35

1734

0.16

1.2

9.8

12.3

0.552

0.536

50

2482

0.16

1.5

11.9

14.8

0.39

0.379

70

3485

0.16

1.5

13.6

17

0.276

0.268

95

4726

0.16

1.8

15.6

19.5

0.204

0.198

Cable Photols:

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Richard Li

Phone: 0086-13396732591

Tel: 0086-13396732591

Email: richard@handwecable.com

Add: Floor 5, No. 137-138, Lane No. 456, Dieqiao Road,Pudong New District, Shanghai, China

+8613396732591

+8613396732591 +8613396732591

+8613396732591 Handwe Industry

Handwe Industry Handwe Industry

Handwe Industry