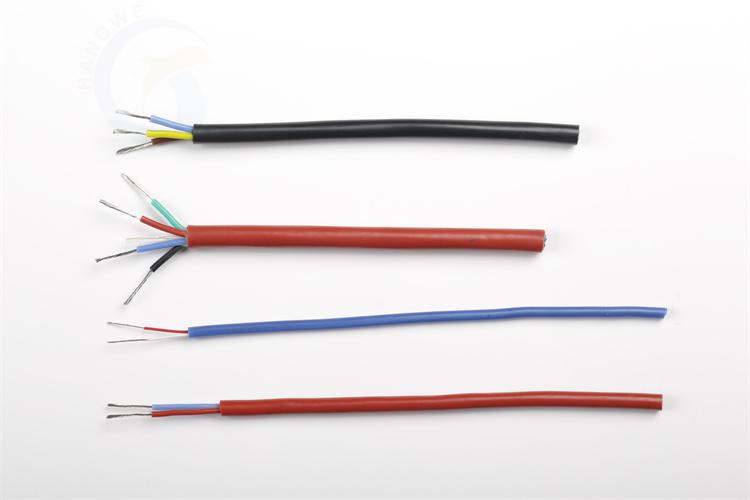

silicone rubber cable

Silicone Rubber High Temperature Control Cable Wire 180°C 450/750V

- AC rated voltage:AC UO/U 450/750V

- Maximum operating temperature 180°C

- Silicon rubber sheath

- Fixed laying -60°C, non-fixed laying -20°C

- Product description: This product is suitable for AC rated voltage 450/750V and below mobile or fixed laying electrical signal transmission cable or instrument cable has good thermal stability, in high temperature, low te

Silicone Rubber High Temperature Control Cable Wire 180°C 450/750V

TECHNICAL DATA

AC rated voltage:AC UO/U 450/750V

Maximum operating temperature 180°C

Minimun ambient temperature:Silicon rubber sheath : Fixed laying -60°C, non-fixed laying -20°C

Laying of cable installation temperature should be not lower than -20°C

Silicone Rubber High Temperature Control Cable Wire 180°C 450/750V is suitable for AC rated voltage 450/750V and below mobile or fixed laying electrical signal transmission cable or instrument cable has good thermal stability, in high temperature, low temperature,corrosive in good electrical properties and flexibility, suitable for metallurgy,electric power,petrochemical and other industries have special requirements such as mobile temperature occasions

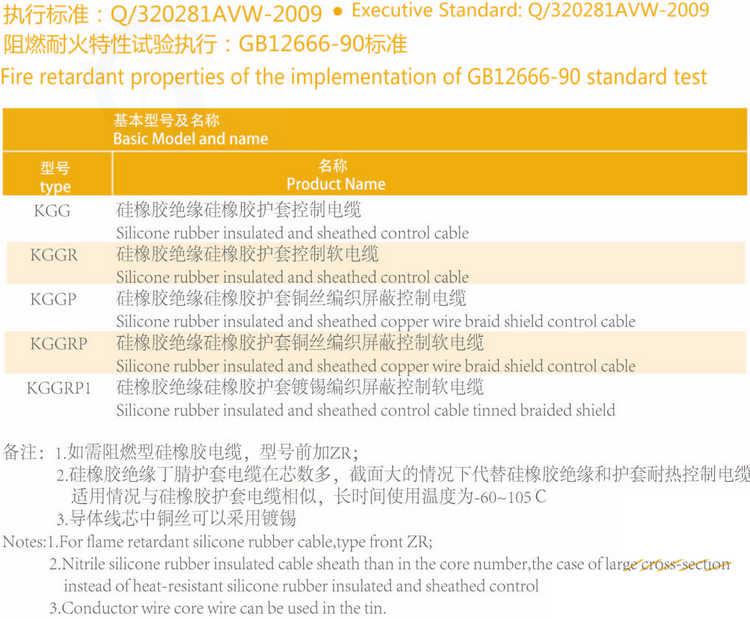

Executive Standard: Q/320281AVW-2009

Fire retardant properties of the implementation of GB12666-90 standard test

Basic Model and name

type Product Name

KGG Silicone rubber insulated and sheathed rigid solid conductor control cable

KGGR Silicone rubber insulated and sheathed flexible tranded conductor control cable

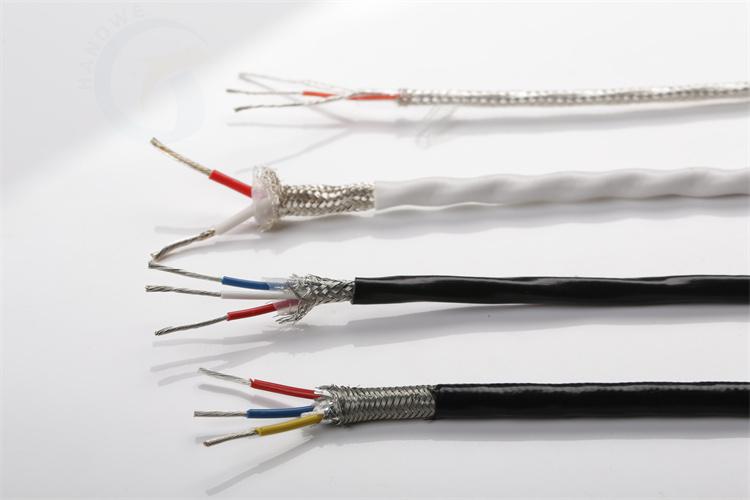

KGGP Silicone rubber insulated and sheathed copper wire braid shield rigid solid conductor control cable

KGGRP Silicone rubber insulated and sheathed copper wire braid shield flexible tranded conductor control cable

KGGRP1 Silicone rubber insulated and sheathed control cable tinned braided shield flexible tranded conductor control cable

Notes:

1 .For flame retardant silicone rubber cable, add ZR in front of the type

2. Nitrile silicone rubber insulated cable sheath are used the case of large core number & large cross-section instead of heat-resistant silicone rubber insulated and sheathed control cable

3. Conductor wire core wire can be used in the tinned copper.

Code meanings

ZR Flame retardant silicone rubber

K Control Cable

G Silicone rubber

G Silicone rubber

YVF Nitrile PVC

P Copper braid shielding

P1 Tinned copper shielding

A Solid rigid strand conductor

B 7 strands conductor

C Class 5/6 multi-strand conductor

The main technical indicators

1 Finished cable conductor DC resistanue (in accordance with the provisions of GB3956)

2. At 20C, the insulation resistance of not less than 500M Ohm /KM

2. Finished cable AC 50HZ 3.0KV/5mir) withstand voltage test without breakdown

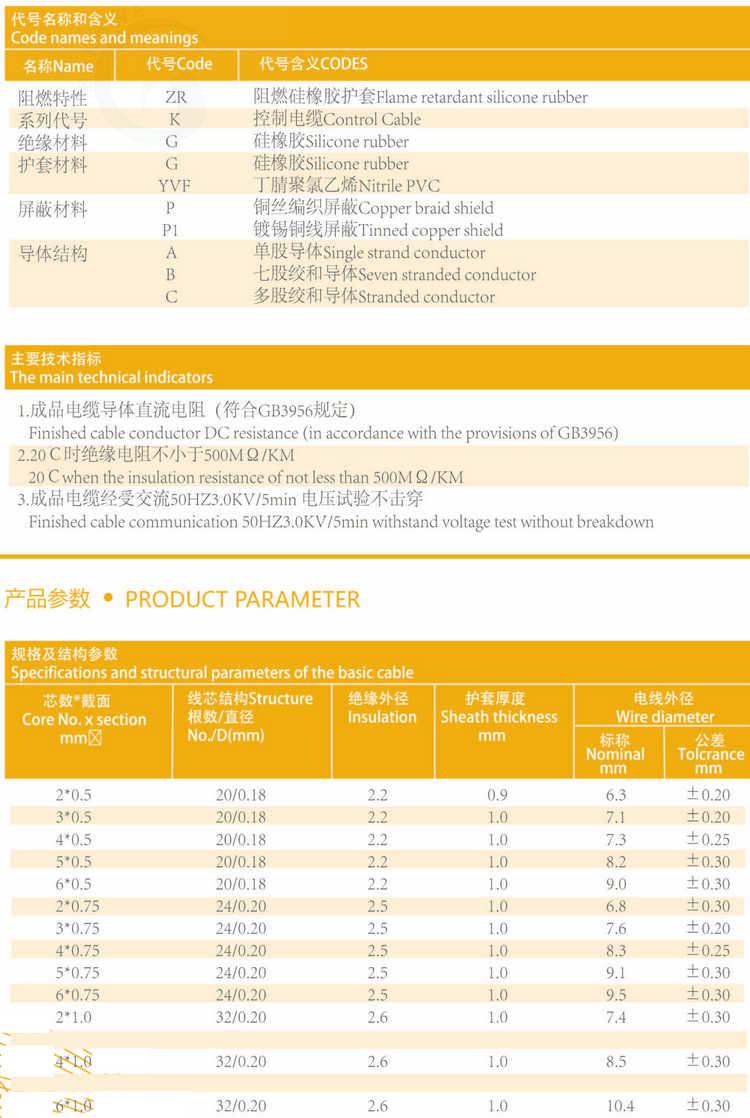

PRODUCT PARAMETER

Specifications and structural parameters of the cable

| Core No. x section mm | Structure / No./OD (mm) | Insulation OD mm | Sheath thickness mm | Wire diameter | |

| Nominal mm | Tolerance mm | ||||

| 2*0.5 | 20/0.18 | 2.2 | 0.9 | 6.3 | ±0.20 |

| 3*0.5 | 20/0.18 | 2.2 | 1 | 7.1 | ±0.20 |

| 4*0.5 | 20/0.18 | 2.2 | 1 | 7.3 | ±0.25 |

| 5*0.5 | 20/0.18 | 2.2 | 1 | 8.2 | ±0.30 |

| 6*0.5 | 20/0.18 | 2.2 | 1 | 9 | ±0.30 |

| 2*0.75 | 24/0.20 | 2.5 | 1 | 6.8 | ±0.30 |

| 3*0.75 | 24/0.20 | 2.5 | 1 | 7.6 | ±0.20 |

| 4*0.75 | 24/0.20 | 2.5 | 1 | 8.3 | ±0.25 |

| 5*0.75 | 24/0.20 | 2.5 | 1 | 9.1 | ±0.30 |

| 6*0.75 | 24/0.20 | 2.5 | 1 | 9.5 | ±0.30 |

| 2*1.0 | 32/0.20 | 2.6 | 1 | 7.4 | ±0.30 |

| 4*1.0 | 32/0.20 | 2.6 | 1 | 8.5 | ±0.30 |

| 6*1.0 | 32/0.20 | 2.6 | 1 | 10.4 | ±0.30 |

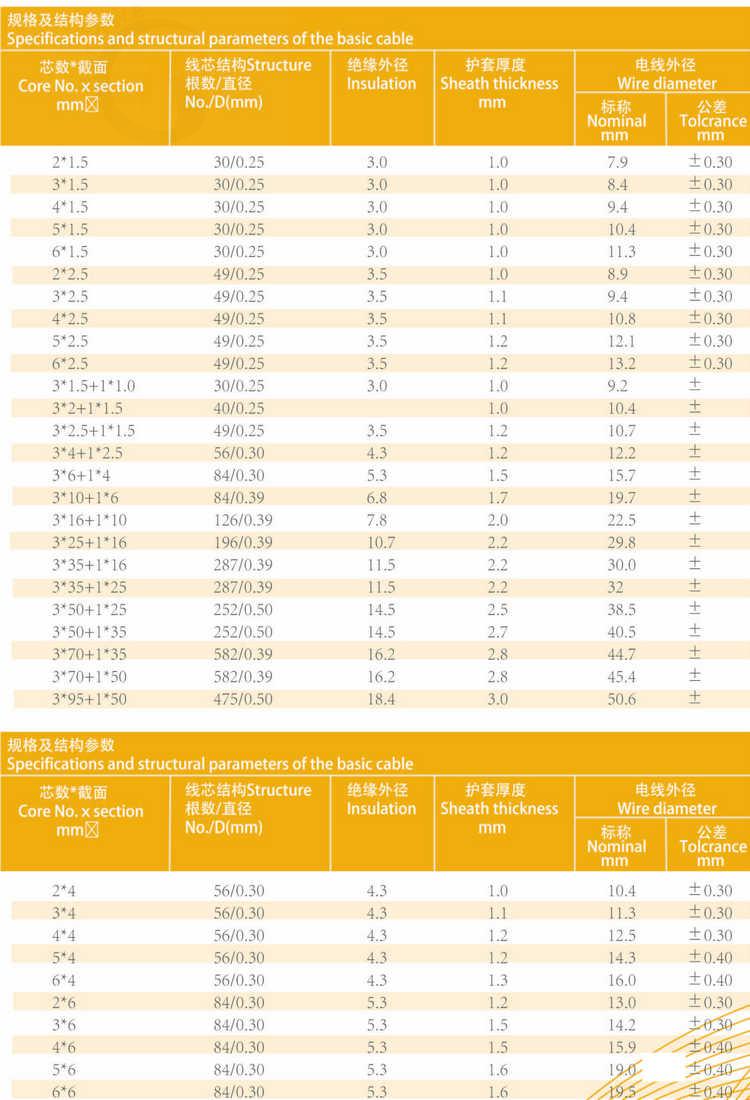

| MS Core No. x section mm | Structure / No./OD(mm) | Sheath thickness mm | Sheath thickness mm | Wire diameter | |

| Nominal mm | Tolerance mm | ||||

| 2*1.5 | 30/0.25 | 3.00 | 1.00 | 7.90 | ±0.30 |

| 3*1.5 | 30/0.25 | 3.00 | 1.00 | 8.40 | ±0.30 |

| 4*1.5 | 30/0.25 | 3.00 | 1.00 | 9.40 | ±0.30 |

| 5*1.5 | 30/0.25 | 3.00 | 1.00 | 10.40 | ±0.30 |

| 6*1.5 | 30/0.25 | 3.00 | 1.00 | 11.30 | ±0.30 |

| 2*2.5 | 49/0.25 | 3.50 | 1.00 | 8.90 | ±0.30 |

| 3*2.5 | 49/0.25 | 3.50 | 1.10 | 9.40 | ±0.30 |

| 4*2.5 | 49/0.25 | 3.50 | 1.10 | 10.80 | ±0.30 |

| 5*2.5 | 49/0.25 | 3.50 | 1.20 | 12.10 | ±0.30 |

| 6*2.5 | 49/0.25 | 3.50 | 1.20 | 13.20 | ±0.30 |

| 3*1.5+1*1.0 | 30/0.25 | 3.00 | 1.00 | 9.20 | ±0.30 |

| 3*2+1*1.5 | 40/0.25 | 3.50 | 1.00 | 10.40 | ±0.30 |

| 3*2.5+1*1.5 | 49/0.25 | 3.50 | 1.20 | 10.70 | ±0.30 |

| 3*4+1*2.5 | 56/0.30 | 4.30 | 1.20 | 12.20 | ±0.30 |

| 3*6+1*4 | 84/0.30 | 5.30 | 1.50 | 15.70 | ±0.30 |

| 3*10+1*6 | 84/0.39 | 6.80 | 1.70 | 19.70 | ±0.30 |

| 3*16+1*10 | 126/0.39 | 7.80 | 2.00 | 22.50 | ±0.30 |

| 3*25+1*16 | 196/0.39 | 10.70 | 2.20 | 29.80 | ±0.30 |

| 3*35+1*16 | 287/0.39 | 11.50 | 2.20 | 30.00 | ±0.30 |

| 3*35+1*25 | 287/0.39 | 11.50 | 2.20 | 32.00 | ±0.30 |

| 3*50+1*25 | 252/0.50 | 14.50 | 2.50 | 3&5 | ±0.30 |

| 3*50+1*35 | 252/0.50 | 14.50 | 2.70 | 40.50 | ±0.30 |

| 3*70+1*35 | 582/0.39 | 16.20 | 2.80 | 44.70 | ±0.30 |

| 3*70+1*50 | 582/0.39 | 16.20 | 2.80 | 45.40 | ±0.30 |

| 3*95+1*50 | 475/0.50 | 18.40 | 3.00 | 50.60 | ±0.30 |

| 2*4 | 56/0.30 | 4.30 | 1.00 | 10.40 | ±0.30 |

| 3M | 56/0.30 | 4.30 | 1.10 | 11.30 | ±0.30 |

| 4*4 | 56/0.30 | 4.30 | 1.20 | 12.50 | ±0.30 |

| 5M | 56/0.30 | 4.30 | 1.20 | 14.30 | ±0.30 |

| 6*4 | 56/0.30 | 4.30 | 1.30 | 16.00 | ±0.30 |

| 2*6 | 84/0.30 | 5.30 | 1.20 | 13.00 | ±0.30 |

| 3*6 | 84/0.30 | 5.30 | 1.50 | 14.20 | ±0.30 |

| 4*6 | 84/0.30 | 5.30 | 15.00 | 15.90 | ±0.40 |

| 5*6 | 84/0.30 | 5.30 | 1.60 | 19.00 | ±0.40 |

| 6*6 | 84/0.30 | 5.30 | 1.60 | 19.50 | ±0.40 |

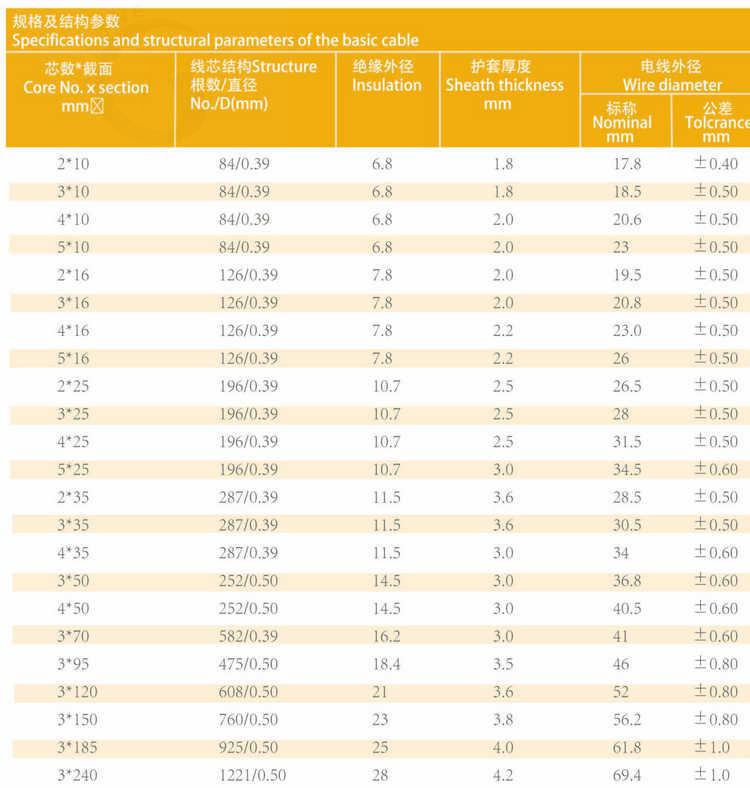

| MS Core No. x section mm | Structure / No./OD(mm) | Sheath thickness mm | Sheath thickness mm | Wire diameter | |

| Nominal mm | Tolerance mm | ||||

| 2*10 | 84/0.39 | 6.8 | 1.8 | 17.8 | ±0.40 |

| 3*10 | 84/0.39 | 6.8 | 1.8 | 18.5 | ±0.50 |

| 4*10 | 84/0.39 | 6.8 | 2 | 20,6 | ±0.50 |

| 5*10 | 84/0.39 | 6.8 | 2 | 23 | ±0.50 |

| 2*16 | 126/0.39 | 7.8 | 2 | 19.5 | ±0.50 |

| 3*16 | 126/0.39 | 7.8 | 2 | 20.8 | ±0.50 |

| 4*16 | 126/0.39 | 7.8 | 2.2 | 23 | ±0.50 |

| 5*16 | 126/0.39 | 7.8 | 2.2 | 26 | ±0.50 |

| 2*25 | 196/0.39 | 107 | 2.5 | 26.5 | ±0.50 |

| 3*25 | 196/0.39 | 10.7 | 2.5 | 28 | ±0.50 |

| 25 | 196/0.39 | 10.7 | 2.5 | 31.5 | ±0.50 |

| 5*25 | 196/0.39 | 10.7 | 3 | 34.5 | ±0.60 |

| 2*35 | 287/0.39 | 11.5 | 3.6 | 2&5 | ±0.50 |

| 3*35 | 287/0.39 | 11.5 | 3.6 | 30.5 | ±0.50 |

| 4*35 | 287/0.39 | 11.5 | 3 | 34 | ±0.60 |

| 3*50 | 252/0.50 | 14.5 | 3 | 36.8 | ±0.60 |

| 4*5() | 252/0.50 | 14.5 | 3 | 40.5 | ±0.60 |

| 3*70 | 582/0.39 | 16.2 | 3 | 41 | ±0.60 |

| 3*95 | 475/0.50 | 18.4 | 3.5 | 46 | ±0.80 |

| 3*120 | 608/0.50 | 21 | 3.6 | 52 | ±0.80 |

| 3*150 | 760/0.50 | 23 | 3.8 | 56.2 | ±0.80 |

| 3*185 | 925/0.50 | 25 | 4 | 61.8 | ±1.0 |

| 3*240 | 1221/0.50 | 28 | 4.2 | 69.4 | ±1.0 |

| MS Core No. x section mm | Structure / No./OD(mm) | Sheath thickness mm | Sheath thickness mm | Wire diameter | |

| Nominal mm | Tolerance mm | ||||

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Richard Li

Phone: 0086-13396732591

Tel: 0086-13396732591

Email: richard@handwecable.com

Add: Floor 5, No. 137-138, Lane No. 456, Dieqiao Road,Pudong New District, Shanghai, China

+8613396732591

+8613396732591 +8613396732591

+8613396732591 Handwe Industry

Handwe Industry Handwe Industry

Handwe Industry